Improving Global Road Safety: Corporate Sector Commitments and Opportunities

Abstract

This paper offers a perspective with recommendations on opportunities for the private sector to improve road safety outcomes globally. Road safety has been recognized as an increasing public health burden that disproportionately affects low- and middle-income countries. In response, in 2010 the UN General Assembly proclaimed the UN Decade of Action for Road Safety 2011–2020 with the official goal of “stabilizing and then reducing” global road traffic fatalities by 2020 (WHO, 2011b). This paper examines how the private sector can contribute to this goal by exploring the shared knowledge, experience, and expertise of companies who maintain global fleets and highlighting some examples of road safety best practices. The primary focus of this report is on cars and roads, which currently represent the dominant transportation investments in most countries and most immediate opportunities for actionable change. The introduction to this paper was based on a review of secondary-source public health data to understand the scope of the road safety problem. The best-practice examples were sourced through questionnaire responses, interviews, and written contributions from five global companies with significant fleet operations in multiple locations. The cases revealed several areas of opportunity where companies can make meaningful contributions to road safety outcomes for their employees, contractors, and communities at large. Through innovation, thought leadership, early adoption and development of technology, marketing, and training, companies are uniquely placed to raise road safety standards and behaviors.

Introduction: The Global Issue

João is a sales representative for a major company in Brazil. Every day, he climbs onto his motorcycle and rides from client to client through the busy streets of Sao Paulo. João is young, bright, and excellent at his job. He doesn’t think about road safety too often. Why would he? He is a sensible, careful, and experienced rider. What he doesn’t realize is that, as a young man on the roads in a middle-income country, João faces a disproportionately high risk of sustaining serious injury or death every day. João’s job presents a significant threat to his health. Like João, billions of people use the world’s roads for work and are faced with the increasing threat of harm every day.

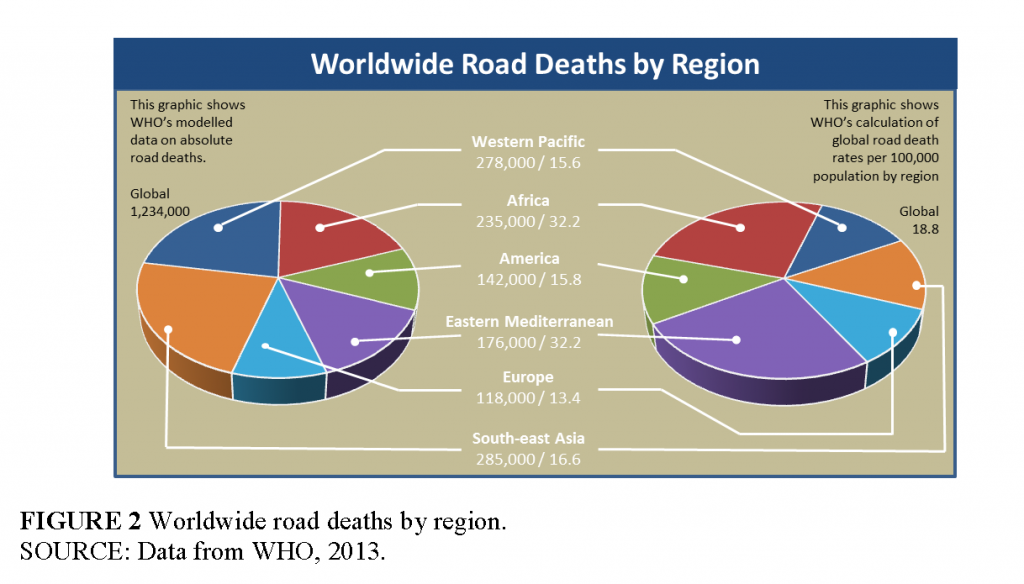

According to the World Health Organization (WHO), in 2013 50 million people were injured and 1.25 million were killed in traffic-related crashes. This already unacceptably high number is expected to increase to 2 million deaths by 2030 (WHO, 2013), which would make traffic-related crashes the fifth leading cause of death globally.

In addition:

- Road traffic is the leading cause of death among young people between the ages of 15 and 29 years.

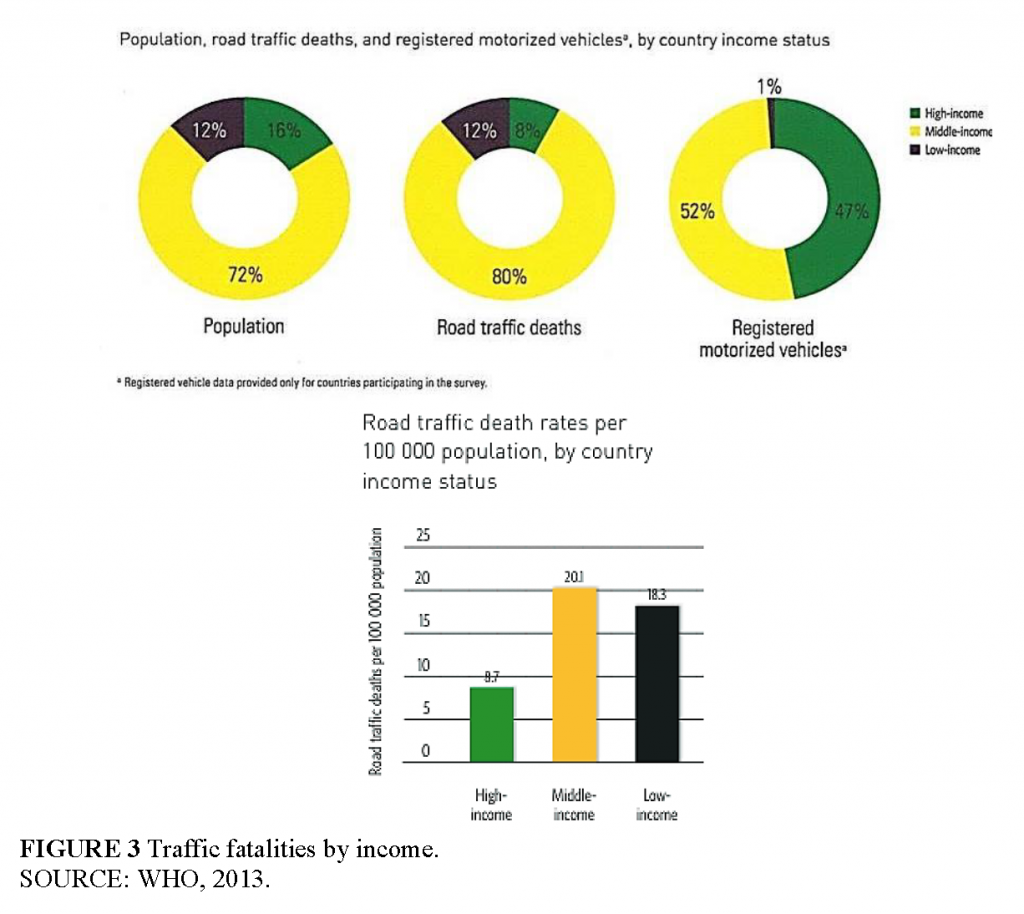

- Ninety-one percent of the global road fatalities occur in low- and middle-income countries although these countries have approximately half of the world’s vehicles.

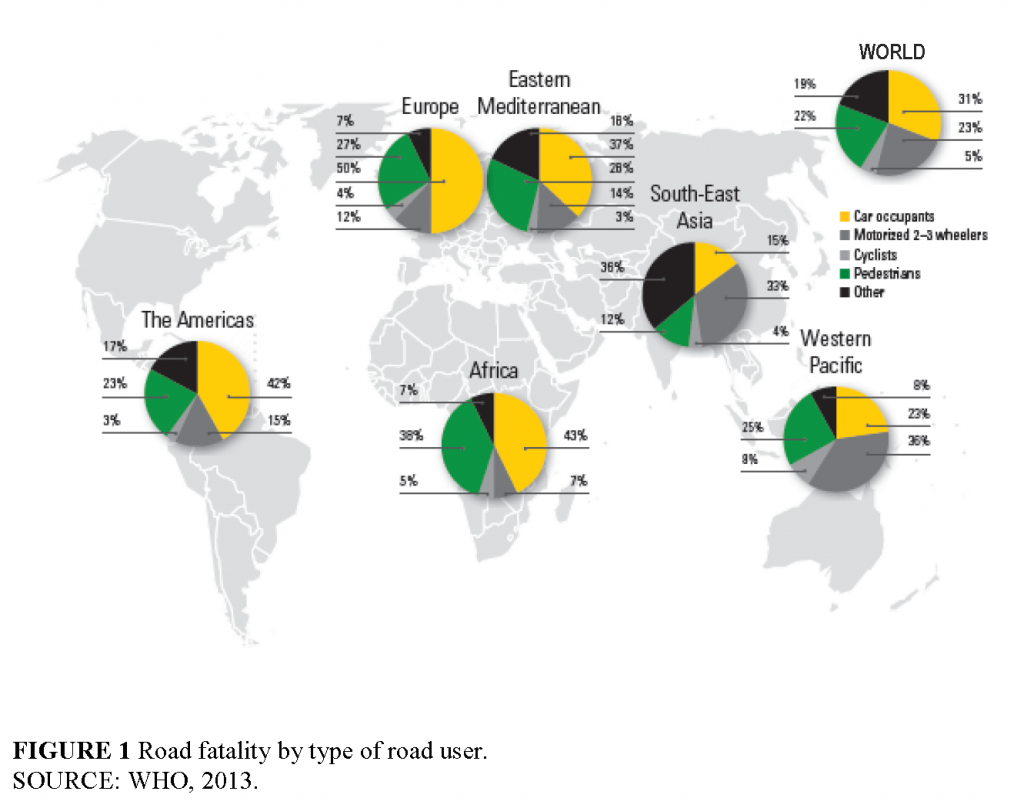

- Half of those dying on the world’s roads are “vulnerable road users”: pedestrians, cyclists, and motorcyclists (Figure 1).

- Without action, road traffic crashes are predicted to result in the deaths of around 1.9 million people annually by 2020.

- Only 28 countries, which represent 7 percent of the world’s population, have adequate policies addressing road fatalities.

As these statistics show, road traffic crashes have a disproportionate impact on the poor. There are more road traffic injuries and fatalities in low- and middle-income countries than in their upper-middle and high-income counterparts (WHO, 2013) due to rapid urbanization and growth in the number of vehicles without the adequate attention to road design and policy formulation (WHO, 2004) (Figures 2 and 3).

Just as this burden disproportionately affects the poor, it is also a health inequity for youth. As noted above, road traffic crashes are the number one cause of death among young people, aged 15–29, worldwide (WHO, 2009)—a segment of the population that is entering its most productive years of life (WHO, 2011a). WHO also estimates that road traffic injuries will be the leading health burden for children over age 5 in developing countries (WHO, 2009).

Beyond their immediate health implications, road traffic crashes have considerable social and economic consequences. Road traffic injuries cost developing countries at least $100 billion per year and place an enormous burden on public resources, such as health systems (WHO, 2013; World Bank, 2002).

The economic impact of road traffic crashes are also felt at the family level. Economically disadvantaged families are affected by both direct medical costs and indirect costs (i.e., lost wages) (WHO, 2013). Many poor people generally lack ongoing support in the event of long-term injury and have limited access to post-crash emergency care, which further compounds this impact (WHO, 2009).

Despite scientific consensus dating back nearly 50 years on road safety as a critical public health issue, (The National Research Council’s 1966 report titled Accidental Death and Disability: The Neglected Disease of Modern Society suggested that “public apathy to the mounting toll from accidents must be transformed into an action program under strong leadership” (NRC, 1966, pg. 5).) the acceptance of this idea in broader society has been slow. The positive news is that in recent years, the global profile of road safety has increased. In 2010 the UN General Assembly proclaimed the UN Decade of Action for Road Safety 2011–2020, with the official goal of “stabilizing and then reducing” global road traffic fatalities by 2020 (WHO, 2011b). According to the UN, with the right action, up to 5 million lives could be saved and 50 million injuries prevented during this period (WHO, 2011c). This result would represent a reduction of about 50 percent on the predicted global death toll by 2020.

Numerous interventions and innovations to reduce the incidence and impact of road traffic crashes also provide hope for a safer future on the world’s roads. The Safe Systems Approach, a feature of Sweden’s Vision Zero initiative, places equal responsibility for road safety on system design and individual road users in recognition of the complexity and need to approach the problem in a multifaceted way (Business Sweden, 2013). Since the implementation of the initiative, Sweden has achieved one of the lowest traffic-related fatality rates in the world. Many cities are adopting this model, particularly in the United States, in an effort to reduce crash risk. For example, the city of Seattle will tackle their “Vision Zero” policy by using “the three E’s” strategy, which seeks to achieve a goal of zero road fatalities and serious injuries by adopting a multifaceted approach through Engineering (i.e., street redesign), Enforcement (i.e., scaling up police efforts), and Education (i.e., advocating for safer streets) (Seattle Department of Transportation, 2012).

Along with government, the private sector has interest in resolving the road safety problem. A significant portion of the financial impact of road traffic crashes falls on companies because such crashes present a risk to employee health and safety and impact the efficiency of transport-related commercial activity. This is particularly the case for companies operating in areas where the road traffic crash burden is high. In the next section, we will explore how the private sector is uniquely positioned to help solve the road safety challenge. By applying knowledge and best practices on road safety, utilizing brand power, and developing innovative solutions, the private sector can help to address this health and development challenge inside and outside of their companies’ walls.

Road Safety Issues for the Private Sector

Ensuring the safety of employees is imperative for all companies. Beyond the fundamental responsibility to keep employees safe, companies also have a clear financial incentive to improve road safety. By doing so, companies can reduce damage to their assets and minimize productivity losses due to employee injury as well as reduce standstill logistics costs. For global companies moving into emerging market economies, improving road safety is particularly important. The disproportionate focus of the road safety burden in these markets presents a heightened risk to company operations and results in a significant increase in the cost of doing business.

Road safety impacts the private sector through three key domains: a company’s fleet operations (i.e., employees who work and drive trucks on the roads), vendors and contractors who service the company (i.e., transport goods for delivery or distribution on behalf of companies and the sales representatives who service these accounts), and employees who commute to work or travel for work. In each of these domains, companies are making great strides in reducing the road safety burden.

According to Eurostat, a linear relationship exists between the number of passenger kilometers (Unit of measurement representing the transport of one passenger by a defined mode of transport (road, rail, air, sea, inland waterways etc.) over one kilometre. Source:http://ec.europa.eu/eurostat/statisticsexplained/index.php/Glossary:Passenger-kilometre (accessed October 13, 2015).) driven by car and road fatalities (European Commission, 2012). By some estimates, more than a quarter of all road traffic incidents involve individuals who are driving as part of their work at the time of the accident (Health and Safety Executive, 2014). As such, irrespective of the size of the company, every organization should take responsibility by establishing road safety programs to protect their employees. These programs can range from formalized training to establishing simple policies, such as providing employees safe driving education, encouraging wearing seatbelts and helmets, and ensuring vehicles are safe on the road. Even the simplest of these policies can help reduce injuries and deaths and result in measurable benefits, such as saving lives, improving productivity, and reducing vehicle repair bills, workers’ compensation insurance premiums, and lost time at work. These policies can also reduce stress and improve employee morale, a benefit often not considered or measured. By establishing road safety policies and procedures, companies will improve not only the safety of their own employees who drive for work purposes but also the safety of others sharing streets, highways, and road systems. Appendix 1 provides a sample of a Work-Related Road Safety Checklist provided by the Health and Safety Executive, the United Kingdom’s public watchdog for workplace health and safety (Health and Safety Executive, 2014).

Developing Leading Road Safety Practices across Fleet Operations

Many companies are enhancing road safety for their employees through regular upgrades to the safety features across their vehicle fleets. Vehicle safety technology is a critical factor in employee safety on the roads and can take various forms. For example, global beverage company Anheuser-Busch InBev (AB InBev) is installing telemetry systems in all delivery trucks in its fleet and company-owned cars and motorcycles; these systems monitor driver behavior remotely to ensure compliance with safety procedures and provide data for continuous improvement of fleet safety systems. The data include speed in relation to local speed limits, rapid acceleration/deceleration, seatbelt use, and other information.

United Parcel Service (UPS), the world’s largest package delivery company, is also making significant investments. Information gathered from numerous driver focus groups and manufacturer interactions have led to a more driver-friendly environment. Investments in vehicles include wider user egress and entry ways and many more improved lines of sight to increase visual acuity. UPS is also using vehicle telematics to help promote vehicle reliability and serviceability and is incorporating an antilock braking system into future vehicle purchases. These investments are made to ensure that all the company’s vehicles meet rigorous safety standards and to provide drivers with the safest work environment possible.

Ryder, a fleet and supply chain management company, implements a vehicle safety package that offers collision mitigation, lane departure warning, adaptive cruise control, roll stability, and LED lights. This package allows drivers to see farther up the road with less fatigue and eye strain while encouraging them to utilize the turn signal prior to changing lane positions. In addition, it warns drivers any time the vehicle begins to drift outside of its current lane of travel. Finally, the safety package maintains a following distance of no less than 3.6 seconds and brakes automatically any time it senses that the vehicle is starting to take a turn too fast or that a collision with a slower moving vehicle is imminent.

Global retailer Walmart equips its trucks with a standard safety package that includes collision mitigation, lane departure warning, adaptive cruise control, and roll stability. In addition, Walmart continually tests and evaluates new and updated technology to enhance the performance and safe operation of its trucks. (Information on Walmart’s road safety initiatives was provided by Mike Noble, Senior Director of Logistics Fleet Safety at Walmart.)

Beyond technological investments, companies also recognize the importance of driver behavior, training, and scheduling to reduce the incidence of road crashes. UPS, Ryder, Walmart, and AB InBev all adhere to all Department of Transportation scheduling regulations in the United States and require that any third-party transportation company doing business for them to follow all local government regulations internationally. For example, all four companies have implemented restricted number of hours per driver shifts, a policy supported by procedures to rearrange delivery routes or find replacement drivers in the event that the time limit may be exceeded.

For Ryder, recruitment is also a significant part of its road safety strategy. Ryder hires only experienced drivers. The company undertakes a detailed driver experience review confirmed through background checks. During the recruitment process, driver skill levels are evaluated and confirmed through road tests conducted by an experienced driver trainer or the applicant’s hiring manager. Once an applicant is hired, he or she completes new hire safety orientation in order to understand the company’s requirements for working and driving safely. Building on this recruiting and onboarding process, Ryder is currently rolling out a new program that defines, trains, and qualifies Certified Driver Trainers throughout its driver group. These drivers are selected for their ability to instill Ryder’s safety culture in new hires and mentor existing drivers who require additional training across its locations.

Walmart also recruits only experienced drivers, specifically drivers who have at least 3 years of driving experience and who have not had a preventable accident in the past 3 years, have had no Department of Transportation recordable accidents in the previous 10 years, and have never been involved in a preventable accident resulting in a fatality or catastrophic injury. All candidates are put through an extensive road test to gauge their skills, knowledge of the regulations, and ability to safely operate a vehicle. Once hired, drivers participate in a weeklong orientation, which includes defensive driving instruction, before working with a trainer for 1 to 2 weeks. Thereafter, drivers are required to attend an annual defensive driving course.

Many companies mandate extensive driver training. Both UPS and AB InBev have road safety training requirements for drivers (both practical and theoretical), including compulsory annual refresher courses. If an AB InBev driver is involved in a crash, he or she must complete this training again before returning to the roads. At UPS, driver certification includes a process called “Space and Visibility Training”—a 10-point commentary stressing the importance of space and visibility when driving. Tractor trailer drivers receive 80 hours of classroom training, and package car drivers receive 20 hours. A safety manager or certified team leader accompanies new drivers during their first 22 days of probation. Three safety rides are mandated, with multiple 30-minute intensive interactions between the trainee and team leader. During this interaction, instructors call out everything that the driver should be aware of or anticipating. This active and comprehensive critique of driver performance is repeated until the trainee demonstrates an acceptable level of proficiency. In addition, all driver work groups are provided a 3-minute prework communications meeting prior to driver start-up, where business matters are reviewed; every prework communications meeting is followed by either a management or driver member giving a safety tip for the day.

At Ryder, all drivers complete both monthly and quarterly training on the basis of the work they perform, the injury and collision trends seen throughout the company, and the regulatory changes made within the industry. This training may include regulatory requirements such as observing hazardous material compliance, maintaining hours of service logs, and completing both pretrip and posttrip vehicle inspections or cargo securement safety. In addition to the regulatory training requirements, all Ryder drivers must complete quarterly collision and/or injury prevention training. This training begins with a driver code of conduct lesson at the start of each year. In addition to this training, drivers are required to take quarterly lessons selected from developing collision trends. This ongoing defensive driver training includes courses such as speed and space management, lane changes and intersections, roll-over prevention, and avoidance of rear-end collisions.

Walmart has implemented a unique dispatch philosophy. Walmart does not dispatch drivers on the basis of the available hours reflected in its electronic logging system. Rather, Walmart drivers are dispatched on the basis of the hours drivers state they are able to run. This dispatch philosophy allows drivers to control their schedule and adjust it on the basis of their individual needs and provides drivers the freedom to take additional or longer breaks as necessary.

Some companies adjust their training programs to suit the local conditions for their drivers. Although most of AB InBev’s road safety driver training is standardized across the world, in some markets the company has tailored driver training for locations with unique road safety dangers. For example, the driver training program in Belgium includes a specialized module on bicycle safety, given the high prevalence of commuting cyclists and bike infrastructure on the roads in that country. Ryder also takes a localized approach, employing an online system, RyderSTAR (Safety Tracking and Reporting), that develops a monthly safety plan for each location that is unique as it relates to its operational profile developed at the beginning of the calendar year. This monthly safety plan defines what each location is required to do as it relates to education and training, incident investigation, inspections and audits, rules and procedures, safety and health awareness, and so forth.

Alongside these policies and procedures, companies are providing incentives to their employees to achieve greater road safety outcomes. UPS has implemented the Circle of Honor program and the Safe Driving Hall of Fame Program, which publicly recognize drivers with exemplary safety records. Both annual programs reward drivers who have no avoidable accidents during the course of a year.

UPS has more than 7,800 active Circle of Honor drivers globally. UPS’s safe driving honor program recognizes drivers for maintaining an accident-free record. Drivers who attain the significant milestone of 25 years without an accident receive a specialized uniform patch displaying the number of years they have attained. In addition, Circle of Honor drivers receive a jacket, plaque, pin, and certificate highlighting their achievement. Drivers are honored with a breakfast celebration that includes their spouse, local dignitaries, and coworkers.

In an effort to increase safety awareness and performance, Walmart has implemented a quarterly safety incentive program. Drivers earn this incentive each quarter they complete without being involved in a preventable accident or incident. Drivers are paid an additional rate per mile for each mile driven during the quarter and receive a “safety day,” which is a paid day off.

In addition, Walmart drivers are recognized for their safe driving history in 500,000-mile increments. Drivers receive uniform patches and truck decals displaying their safety driving history. Drivers who are able to drive 3 million accident-free miles receive a special truck containing numerous upgrades over the standard fleet truck and a unique color to recognize their achievement. This achievement reflects more than 20 years of accident-free driving. Walmart has awarded 137 drivers a 3-million-mile truck. Drivers who achieve 4 million miles of accident-free driving are given the opportunity to purchase a truck set to their personal specifications, including color and any amenities they choose. This achievement recognizes approximately 30 years of accident-free driving. To date, Walmart has awarded a 4-million-mile truck to two drivers.

Walmart also strongly encourages its drivers to participate in the state and national truck driving championships and hosts its own internal truck driving championship. To participate in the state and national competitions, drivers are required to be accident-free (both preventable and nonpreventable) for the previous year and are required to work for a minimum of 11 of the previous 12 months. The competitors therefore must continuously exhibit defensive driving skills throughout the year as well as follow safe work practices to keep from missing time due to on-the-job, as well as off-the-job, injuries. The competitions test not only driving skills but also knowledge of the rules and regulations governing commercial driving and drivers’ ability to inspect their vehicles to identify defective conditions.

To ensure that its road safety systems are continually improved and updated, AB InBev conducts regular benchmarking activities with other organizations to learn new and better methods to achieve greater road safety outcomes. These and other road safety best practices are shared throughout the company via dedicated internal forums. Similarly, safety incidents are reported and discussed across employee safety working groups to understand the root causes and potential risk mitigation strategies for each incident.

Working with Vendors and Contractors to Improve Road Safety Outcomes

Many companies are reaching beyond the activities of their employees to ensure that road safety best practices extend to their vendors and contractors. Supplier contracts that stipulate road safety requirements for contract drivers are becoming commonplace.

AB InBev also requires its contractors in some countries to complete a certification process for contractor vehicles to ensure that they meet the minimum safety requirements set by the company, and it requires all contractors hired by the company to complete a defensive driver training course. This defensive driver course is even required in Brazil for its contracted taxi services.

Improving Road Safety Outcomes for Commuting Employees

Commuter safety is also an important priority for companies, as it applies to all employees. Many companies are extending road safety innovation beyond their fleets to ensure that other employees are traveling to and from work safely. Companies have extensive programs of employee commuter training initiatives in place, including motorcycle safety, cycling safety, and defensive driver training, where families of company employees are invited to attend road safety activities and training programs. For example, in alignment with the World Day for Safety and Health at Work in April this year, six companies—AB InBev, AIG, AT&T, PepsiCo, Ryder, and Walmart—participated in the Together for Safer Roads’ World Safety Day initiative (see more information about Together for Safer Roads in next section) where they spread awareness about the importance of road safety among their millions of employees globally. During this period, they also directly engaged 500,000 of their employees through in-person safety events, pledges, and online activities concerning ways the employees could help to make the roads safer in their communities, including not texting and driving; buckling seatbelts; respecting speed limits; performing 360 reviews on vehicles before departing, and not drinking and driving.

What the Private Sector Can Do for Road Safety?

While the private sector will continue to ensure the safety of its drivers, contractors, and commuting employees, companies also have the opportunity to improve road safety outcomes for the broader public. By harnessing the power of corporate resources and presence in our communities, the improvements in road safety driven by the private sector can extend well beyond company fleet operations.

A current example of this wide-scale contribution to global road safety both inside and outside company operations is the Together for Safer Roads coalition, which was launched at the United Nations in November 2014 by 11 leading companies. (More information can be found in the Together for Safer Roads, World Safety Day 2015 Summary Report. http://www.togetherforsaferroads.org/content/dam/universaltemplate/TSR/downloads/english/World%20Safety%20Day%20Report.pdf) Coalition members include AB InBev, AIG, AT&T, Chevron, Ericsson, Facebook, IBM, iHeartMedia, PepsiCo, Ryder, and Walmart.

Together for Safer Roads members are working in four core areas:

- safer roads, vehicles, and systems;

- safer road users;

- safer companies; and

- advocacy and thought leadership.

Future coalition efforts will include benchmarking best practices that advance traffic safety cultures among companies and partners; convening stakeholders in key cities to focus on strategies for reducing injuries and fatalities; identifying ways that technology and data can support road safety; advocating for more funding and support for country road safety initiatives; and raising global awareness of this important issue. These objectives are in line with those of the United Nations Decade of Action for Road Safety, which calls for significant action before 2021 to cut the number of traffic-related fatalities in half.

The coalition is advised by an independent expert panel of eminent leaders in road safety that draws together insights and knowledge across this issue and geographies. Dr. Kenneth Moritsugu, former acting U.S. surgeon general, leads this panel. The goal of Together for Safer Roads is to establish a global partnership with governments, municipalities, companies, and citizens by establishing holistic and collaborative networks to support safer road programs.

To raise awareness about the coalition, Walmart has purchased 12 trailers that have been wrapped with Together for Safer Roads branding. These trailers are staged throughout the United States and are used as a “rolling billboard” for the road safety campaign at a variety of public and private events. The Walmart Road Team drivers attend these events on behalf of the company, provide literature to the attendees of the event, and encourage the attendees to sign the trailer and commit to distraction-free driving.

A current example of a corporate and community partnership to improve road safety is the Road Code program, which is a partnership between the UPS Foundation and the Boys and Girls Clubs of America. Based on the same methods used by UPS drivers who are recognized for their safe driving techniques, the program features a combination of classroom instruction, games, videos, and virtual driving simulation taught to teens by UPS employee volunteers. The program has reached more than 20,000 teens 13–18 years of age in the United States and four other countries since 2009.

To provide a visual reminder to communities of the importance of seatbelts, Walmart has recently started installing orange seatbelts in its vehicles so that the seatbelts are clearly visible to other motorists on the road.

Alongside these ongoing efforts, companies can:

- generate a global dialogue between different stakeholder groups—including governments, nonprofits, academic institutions, and the private sector—that can impact the road safety issue. Companies can convene these multisectoral stakeholders on a neutral platform through which new evidence and best practices can be shared, opportunities for collaboration can be identified, and safety science can be advanced.

- improve the standards of road safety performance across the private sector by developing and publishing a sector-wide best practices report on corporate performance around road safety. For example, by building on the selection of insights contained in the previous section of this paper, companies could create a more comprehensive assessment of private sector road safety best practices, contributing to a forum for cross-industry learning and improvement.

- innovate, test, and scale up technological innovations in road and vehicle safety through early adoption and testing of road safety technology. With the increase of telemetry monitoring technology in fleet vehicles, the increased use of innovations such as crash sensor technology in the broader public is not far away. In anticipation of wide-scale adoption, companies will play an important role in installing, testing, and improving this innovation. The potential for crash sensor technology and automatic braking to prevent collisions has the potential to revolutionize road safety for all drivers.

- develop a road safety reporting and measurement index to achieve greater consistency in road safety reporting and measurement across the private sector. Similar to indices that focus on elements of corporate performance like sustainability reporting, such a tool would provide companies with a consistent framework to gauge corporate road safety performance. By incorporating the pillars of the UN Decade of Action, it could also advance the UN’s road safety objectives while achieving greater clarity about the contribution of companies to global road traffic injury and deaths worldwide.

- support a monitoring, learning, and evaluation system for all road safety efforts to ensure continuous improvement across the private sector. By ensuring that all road programs are evaluated and that the lessons are shared, companies will be able to build a collective knowledge base on effective road safety interventions. Beyond simply reporting, companies need to participate in appropriate channels to share lessons learned in pursuit of continuous improvement. This effort requires a structured, ongoing dialogue about successful and unsuccessful road safety investments and programs. Among other inputs, the results of the sector benchmarking efforts noted in the previous recommendation could inform this learning system.

- work with country leadership to improve road safety infrastructure and planning. This goal may be achieved by companies supporting government commitments to road safety under the Sustainable Development Goals (17 Goals and 169 targets that constitute an integrated, indivisible set of global priorities for sustainable development. Source: https://sustainabledevelopment.un.org/focussdgs.html (accessed October 13, 2015)), such as investments in mass transit for large transportation projects (as alternatives to more roads and cars), especially in cities that require city transport for workers. It may also be achieved by working with government to ensure adequate road safety planning when roads are upgraded or replaced. Examples include providing adequate sidewalks and protective street crossing options for pedestrians or improving bicycle infrastructure that promotes pedestrian safety and health through exercise and reduced pollution.

- utilize their marketing expertise and global reach to spread positive messaging about road safety in local communities (e.g., the use of helmets while on motorcycles, seatbelt use, and pedestrian safety). By using these channels, companies can disseminate essential road safety messages to other companies and public road users.

Conclusion

Road safety problems are scientific and technical in content and cut across the concerns of many government agencies, scientific disciplines, and sectors of society. (Language originally cited in 1989 by the Committee on Risk Perception and Communication, National Research Council, referring to communication around public health messaging.) Addressing the road safety burden is in the mutual interest of all these actors. The most successful road safety programs that exist today, such as Sweden’s Vision Zero initiative, recognize this complexity and mutual interest and approach the problem in a multifaceted way. The private sector is one of many actors that can help to improve the problem. This paper outlines some of the ways in which companies can contribute more to this shared problem, thereby enhancing the quality and depth of the solutions.

Appendix 1

Work-Related Safety Checklist

(Health and Safety Executive, Driving at work: Managing work-related road safety, April 2014, http://www.hse.gov.uk/pubns/indg382.pdf. (Contains public sector information published by the Health and Safety Executive and licensed under the Open Government License)

Working through this checklist and thinking about the three areas of safe driver, safe vehicle and safe journey will help you manage work-related road safety effectively.

Safe Driver

Are your drivers competent and capable of doing their work in a way that is safe for them and other people?

- Have you specified what levels of skill and expertise are required to do the job safely and how do you ensure these are met?

- Do you check the validity of driving licenses on recruitment and periodically afterwards?

- What are you doing to make sure your drivers are aware of company policy on work-related road safety and understand what is expected of them?

- Could you use written instructions and guidance, training sessions or group meetings to help you communicate your policy more effectively?

Are your drivers properly trained?

- Do you provide general induction training for drivers?

- Do you arrange for drivers to be trained—giving priority to those at highest risk, e.g., those with high annual mileage, poor accident records, or those new to the job?

- Do you find out whether drivers require extra training to carry out their duties safely, such as using defensive driving techniques, or how to load and unload safely?

- Do you consider training about other road users, e.g., cyclists or motorcyclists?

- Do you train on potential risk factors and preventative measures using data on the incidents of crashes and resulting injuries in your company?

- Do you assess training needs periodically, including the requirement for refresher training?

Do you ensure your training providers are competent to deliver the training you need? That they are safe while on the road?

- Do drivers know how to carry out routine safety checks, such as those on lights, tires and wheel fixings, and report any faults?

- Do drivers know how to correctly adjust safety equipment, e.g., seat belts and head restraints?

- Do drivers know how to use anti-lock braking systems (ABS) properly?

- Do drivers know what to do to ensure they are safe if their vehicle breaks down, e.g., use safety warning triangles and high-visibility jackets?

- Do you need to provide a handbook for drivers giving advice on road safety?

- Do drivers know they must not drive under the influence of drink or drugs?

- Do drivers know they must not use a hand-held mobile phone while driving and that even using a hands-free phone can seriously affect concentration?

- Are drivers aware of the height of their vehicle, both laden and empty? There are estimated to be around three to six major bridge strikes every day.

- Do you make sure crash helmets and protective clothing for motorcycle and bicycle riders are of the appropriate standard?

Are your drivers sufficiently fit and healthy to drive safely and not put themselves or others at risk?

- Do drivers of heavy lorries [trucks], for whom there are legal requirements for medical examination, have the appropriate medical certificate?

- Do you remind drivers that they must satisfy the eyesight and other health requirements of the Highway Code [United Kingdom’s highway code for all road users] and DVLA [Driver and Vehicle License Agency]?

- Have you told drivers they should not drive while taking medicine that might impair their judgment? If there is any doubt, they should ask their GP [general practitioner].

- Are drivers aware of how dangerous tiredness can be and do they know what to do if they start to feel sleepy?

- Do you encourage drivers to report any health concerns?

Do you know your duties under health and safety law when employing contractors and subcontractors?

- Did you know that both you and the contractor you use have duties under health and safety law? An HSE [Health and Safety Executive] leaflet Using contractors: A brief guide provides more advice.

- Do you ensure contractors are competent to do the job safely and without risks to health and safety?

- Do you provide contractors with information on the risks from your activities and the controls you have in place?

- What arrangements do you have in place to ensure contractors tell you about any additional risks from their contracted work?

- Have you set up liaison arrangements for co-operation and co-ordination with all those responsible to ensure the health and safety of everyone concerned?

- Do you decide what you need to do to manage and supervise the work of contractors and agree [to] any controls before work starts?

Safe Vehicles

Are vehicles fit for the purpose for which they are used?

- Do you investigate, when buying new vehicles, which ones are most suitable for driving and for the health and safety of the public?

- Do you make sure your vehicles have driver aids and other safety devices where appropriate, e.g., reversing alarms, camera systems, proximity sensors, and side protection bars for lorries or HGVs [heavy goods vehicles] to protect cyclists?

- Do you ensure privately owned vehicles are not used for work purposes unless they are serviced in line with manufacturers’ recommendations, insured for business use and, where the vehicle is over three years old, have a valid MOT [Ministry of Transport] certificate [UK certification that vehicle meets minimum environmental and road safety standards]?

- Do you ensure drivers and passengers would be adequately protected in an incident, e.g., are any seatbelts, head restraints or airbags correctly fitted, working properly and used?

- Do you ensure vehicles do not exceed their maximum load weight?

- Do you have appropriate arrangements for carrying and properly securing goods and equipment in a vehicle?

Are vehicles maintained in a safe and fit condition?

- Do you ensure daily vehicle checks are carried out?

- Is planned/preventive maintenance carried out in accordance with manufacturers’ recommendations? Remember—an MOT certificate only covers basic defects and does not guarantee the safety of a vehicle.

- Do you ensure tires and windscreen wipers are inspected regularly and replaced as necessary?

- What procedures are there for reporting defects and are they remedied promptly?

- How do you ensure maintenance and repairs are carried out to an acceptable standard?

- Do you have a clear policy that unsafe vehicles should not be driven?

Are you sure that drivers’ health, and possibly safety, is not being put at risk, e.g., from an inappropriate seating position or driving posture?

- Do you take account of ergonomic considerations (e.g., driving position and how accessible the controls are) before buying or leasing new vehicles?

- Do you involve drivers in decisions about seating design?

- Do you provide drivers with guidance on good posture and, where appropriate, on how to set their seat correctly?

Safe Journey

Do you plan routes thoroughly?

- Could you use safer routes which are more appropriate for the type of vehicle doing the journey? Motorways are the safest roads and although minor roads may be fine for cars, they are less safe and could cause difficulties for larger vehicles.

- Does your route planning take account of overhead restrictions, e.g., bridges and tunnels and other hazards, such as level crossings, which may present dangers for long vehicles?

- Can you eliminate or reduce long road journeys by combining with other ways of working or other forms of transport? For example, move goods in bulk by train and then arrange for local distribution by van or lorry, or arrange meetings using conference calls or video links.

- Do you plan routes in consultation with drivers or their representatives, taking account of, for example, the need for rest breaks and access to toilets and washing facilities?

Are work schedules realistic?

- Do you take account of periods when drivers are most likely to feel sleepy when planning work schedules? Sleep-related incidents are most likely between 2 am and 6 am and between 2 pm and 4 pm.

- Have you taken steps to stop employees from driving if they feel sleepy, even if this might upset delivery schedules?

- Where appropriate, are tachographs fitted to vehicles and regularly checked? There are other in-vehicle monitoring and telemetry devices which help to ensure drivers are not putting themselves and others at risk.

- Do you try to avoid periods of peak traffic flow?

- Do you make allowances for new starters, young workers and trainee drivers?

Do you allow enough time to complete journeys safely?

- Do journey times take account of road types and conditions, and allow for rest breaks? The Highway Code recommends that drivers should take a 15-minute break every two hours.

- Would you expect an occasional driver to drive and work for longer than a professional driver? Professional HGV drivers must comply with the rules for drivers’ hours. There is more information at www.gov.uk/drivers-hours/overview.

- Does company policy put drivers under pressure and encourage them to take unnecessary risks, e.g., to exceed safe speeds because of agreed arrival times?

- Do you allow drivers enough time to safely deliver loads?

- How do you ensure drivers are not being asked to work an exceptionally long day? Remember that sometimes they will be starting a journey from home.

- Have you considered advising drivers who work long or irregular hours of the dangers of driving home from work when they are excessively tired? Could they consider an alternative, such as an overnight stay?

Do you consider poor weather conditions, such as snow or high winds, when planning journeys?

- Can your journey times and routes be adjusted to take account of poor weather conditions? Where this is possible, is it done?

- Are vehicles properly equipped to operate in poor weather conditions, e.g. are anti-lock brakes or winter tires fitted and is windscreen washer fluid the correct strength for freezing conditions?

- Do drivers understand what to do to reduce risk, e.g., do drivers of high-sided vehicles know they should take extra care if driving in strong winds with a light load?

- Do drivers feel pressured to complete journeys where weather conditions are exceptionally difficult and do they know who to contact if they need to cancel a journey?

References

- Business Sweden. 2013. Vision Zero initiative. Available at: http://www.visionzeroinitiative.com/en/(accessed April 12, 2015).

- European Commission. 2012. EU transport in figures 2012. Luxembourg, Belgium: Publications Office of the European Union. Available at: http://ec.europa.eu/transport/facts-fundings/statistics/doc/2012/pocketbook2012.pdf

(Accessed October 13, 2015). - Health and Safety Executive. 2014. Driving at work: Managing work-related road safety. April. Available at: http://www.hse.gov.uk/pubns/indg382.pdf.(accessed October 13, 2015)

- National Academy of Sciences and National Research Council. 1966. Accidental Death and Disability: The Neglected Disease of Modern Society. Washington, DC: The National Academies Press. https://doi.org/10.17226/9978

-

National Research Council. 1989. Improving Risk Communication. Washington, DC: The National Academies Press. https://doi.org/10.17226/1189

- Seattle Department of Transportation. 2012. 2012 road safety summit action plan. Seattle, WA: Seattle Department of Transportation. Available at: https://www.seattle.gov/Documents/Departments/beSuperSafe/SDOT-SafetyActionPlanWEB.pdf (accessed July 17, 2020).

- WHO (World Health Organization). 2004. World report on road traffic injury prevention. Geneva, Switzerland: World Health Organization. Available at: https://www.who.int/publications/i/item/world-report-on-road-traffic-injury-prevention (accessed July 17, 2020).

- WHO. 2009. Global status report on road safety: Time for action. Geneva, Switzerland: World Health Organization. Available at: https://www.who.int/violence_injury_prevention/road_safety_status/2009/en/ (accessed July 17, 2020).

- WHO. 2011a. Global burden of disease, 2008. Geneva, Switzerland: World Health Organization.

- WHO. 2011b. Global plan for the Decade of Action for Road Safety, 2011–2020. Geneva, Switzerland: World Health Organization. Available at: https://www.who.int/roadsafety/decade_of_action/plan/en/ (accessed July 17, 2020).

- WHO. 2011c. World unites to halt death and injury on roads. May 6. Available at: http://www.who.int/mediacentre/news/releases/2011/road_safety_20110506/en/ (accessed April 11, 2015).

- WHO. 2013. Global status report on road safety: Supporting a decade. Geneva, Switzerland: World Health Organization.

- World Bank. 2002. Road safety. Available at: http://www.worldbank.org/transport/roads/safety.htm (accessed April 10, 2015).